Differences Between 6061 T6, T651, and T6511 Aluminum Alloys

Differences Between 6061 T6, T651, and T6511 Aluminum Alloys

Aluminum alloys come in various grades, making it challenging to distinguish between them. This article compares three commonly used tempers of the 6061 aluminum alloy: T6, T651, and T6511. While they share the same chemical composition, their mechanical properties—such as machinability, formability, and hardness—differ due to the specific tempering processes they undergo. Understanding these differences will help you select the appropriate temper for your application.

What is 6061 T6 aluminum?

The T6 temper of 6061 aluminum is renowned for its high strength and excellent mechanical properties, making it suitable for various industrial applications. Beyond its alloying elements, the tempering process enhances its performance, providing superior corrosion resistance and good weldability.

Aluminum T6 Temper

The "T" in aluminum temper designations indicates a thermally treated alloy, with the number following it specifying the particular process. In the case of T6, the process involves solution heat treatment followed by artificial aging.

6061 T6 Aluminum Heat Treatment Process

The heat treatment for T6 temper involves several steps:

-

Solution Heat Treatment: The alloy is heated to approximately 525°C (977°F) for several hours to create a homogeneous solid solution.

-

Quenching: The material is rapidly cooled, typically in water, to retain the alloying elements in solution, preventing the formation of precipitates.

-

Artificial Aging: The quenched alloy is reheated to a temperature between 162°C and 205°C (324°F to 401°F) for a specific period, allowing the formation of fine precipitates that enhance strength.

This process results in a material with a balanced combination of strength and corrosion resistance.

6061 T6 Aluminum Mechanical Properties

The T6 temper significantly enhances the mechanical properties of 6061 aluminum:

-

Yield Strength: At least 240 MPa (35,000 psi)

-

Tensile Strength: At least 290 MPa (42,000 psi)

This high strength-to-weight ratio makes it advantageous in various industries.

Applications of 6061 T6 Aluminum

Due to its favorable properties, 6061 T6 aluminum is commonly used in:

-

Marine applications, owing to its corrosion resistance

-

Commercial and military aircraft

-

Bicycle frames

-

Automotive parts

-

Fishing reels and fire ladders

Advantages and Disadvantages of 6061 T6 Aluminum

Advantages

-

High Strength: Provides a robust material suitable for structural applications.

-

Corrosion Resistance: Offers excellent resistance to atmospheric conditions.

-

Good Weldability: Can be welded using various techniques without compromising strength.

Disadvantages

-

Complex Heat Treatment: Requires precise control of heating rates, times, and temperatures.

-

Reduced Ductility: The T6 tempering process can decrease the material's ductility.

-

Cost: The specific heat treatment makes it more expensive than some other tempers.

For thicker aluminum sections, the T6 temper may not be effective due to uneven cooling, necessitating modified processes to ensure uniform properties.

What is 6061 T651 Aluminum?

T651 aluminum is essentially a subset of the T6 temper, offering improved machinability. It's particularly useful in machining processes like grinding, polishing, and cutting.

Aluminum T651 Temper

The T651 temper involves:

-

Solution Heat Treatment: Similar to the T6 process.

-

Stress Relieving by Stretching: The material is mechanically stretched to reduce internal stresses.

-

Artificial Aging: Conducted as in the T6 temper.

This additional stress-relieving step enhances dimensional stability during machining.

T651 Aluminum Heat Treatment Process

After solution heat treatment and quenching, the alloy undergoes:

-

Mechanical Stretching: To alleviate internal stresses, improving stability during machining.

-

Artificial Aging: To achieve the desired mechanical properties.

T651 Aluminum Mechanical Properties

The mechanical properties are comparable to T6, with the added benefit of reduced residual stresses, making it preferable for precision machining applications.

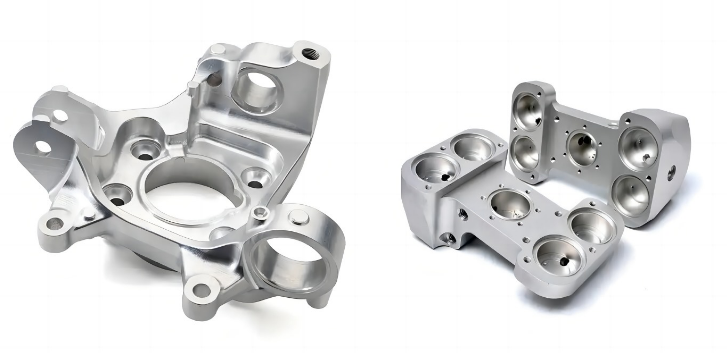

Applications of 6061 T651 Aluminum

Common applications include:

-

Fixtures in aerospace and electrical industries

-

Thick plates and forgings

-

Precision machined components

-

Mold making

-

Automotive parts

Advantages and Disadvantages of 6061 T651 Aluminum

Advantages

-

Retains T6 Properties: Maintains high strength, corrosion resistance, and weldability.

-

Improved Machinability: Reduced internal stresses lead to better dimensional stability during machining.

Disadvantages

-

Increased Cost: Additional processing steps make it more expensive than T6.

-

Longer Processing Time: The stress-relieving step adds to the overall production time.

Physical Properties: Differences Between 6061 T6 and T651

While T6 and T651 tempers share similar mechanical properties, T651 offers better machinability and reduced deformation during machining, making it preferable for complex shapes requiring high precision.

Quality Control in CNC Machining: Best Practices and Strategies

Quality Control in CNC Machining: Best Practices and Strategies